To guarantee your projector operates safely and complies with codes, you need to manage heat and ventilation properly. Keep vents unobstructed, maintain proper clearance, and choose appropriate fans and duct layouts for airflow. Follow local building standards on safe distances and filtration. Regular inspections, proper electrical grounding, and avoiding blockages are essential for compliance. Stick with these guidelines, and you’ll master heat management—more detailed tips are ahead to help you get it right.

Key Takeaways

- Understand projector heat generation and implement effective thermal management to prevent overheating and damage.

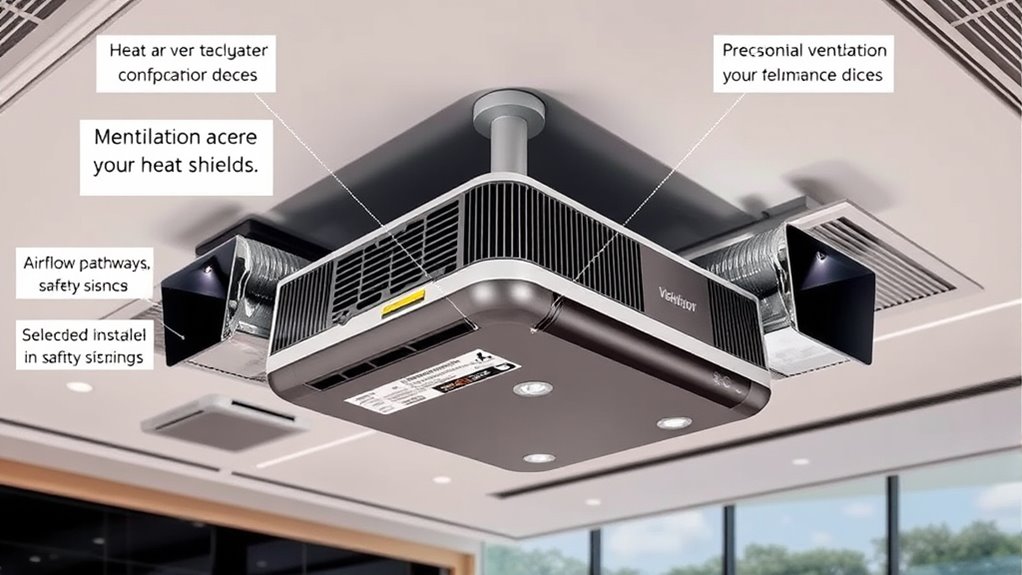

- Ensure proper placement, clearance, and airflow pathways to optimize ventilation and prolong equipment lifespan.

- Comply with local building codes and standards for safe distances, ventilation, and filtration requirements.

- Use appropriately rated fans, seal gaps, and maintain ductwork to ensure consistent airflow and cooling efficiency.

- Conduct regular inspection, cleaning, and temperature monitoring to maintain safety, performance, and regulatory compliance.

AC Infinity CLOUDPLATE T2, Rack Mount Fan 1U, Top Exhaust Airflow, for Cooling AV, Home Theater, Network 19” Racks

An intelligent fan system designed for cooling audio video, DJ, server, network, and IT equipment racks.

As an affiliate, we earn on qualifying purchases.

Understanding Projector Heat Output and Its Implications

Since projectors generate heat during operation, understanding their heat output is crucial for maintaining peak performance and safety. Proper thermal management ensures the device runs efficiently by controlling heat dissipation effectively. When a projector produces excessive heat, it can lead to overheating, which risks damage to internal components and shortens its lifespan. Recognizing how much heat your projector emits helps you choose appropriate cooling solutions and ventilation strategies. Effective heat dissipation prevents thermal buildup and maintains ideal operating temperatures. Without proper thermal management, the projector may shut down unexpectedly or perform poorly. By understanding the heat output, you can implement measures to keep temperatures in check, ensuring long-term functionality and safety in any environment. Additionally, heat output measurement plays a key role in designing compliant ventilation systems that adhere to safety standards.

AC Infinity CLOUDPLATE T1-N, Rack Mount Fan Panel 1U, Intake Airflow, for Cooling AV, Home Theater, Network 19” Racks

An intelligent fan system designed for cooling audio video, DJ, server, network, and IT equipment racks.

As an affiliate, we earn on qualifying purchases.

Key Ventilation Requirements for Safe Operation

Effective ventilation is vital for maintaining safe operating temperatures and preventing overheating in projectors. Proper airflow optimization ensures heat is effectively expelled, reducing the risk of damage or failure. To achieve this, keep vents unobstructed and position the projector in a well-ventilated space. Regular filter maintenance is essential; clogged filters block airflow and cause overheating. Additionally, incorporating good lighting can help monitor airflow and temperature conditions more effectively. Key ventilation requirements include: – Ensuring adequate space around the projector for airflow – Regularly cleaning or replacing filters for ideal filter maintenance – Using vented enclosures or fans if needed to enhance airflow Following these guidelines helps maintain safe operation, prolongs equipment lifespan, and complies with safety standards. Proper ventilation isn’t just about cooling—it’s about safeguarding your investment.

AC Infinity AIRCOM S7, Quiet Cooling Fan System 12" Top-Exhaust for Receivers, Amps, DVR, AV Cabinet Components

A quiet fan system designed for cooling routers, modems, game consoles, and other AV components.

As an affiliate, we earn on qualifying purchases.

Building Codes and Standards Relevant to Projector Installations

Building codes and standards set essential requirements for projector installations to guarantee safety, accessibility, and compliance. These regulations ensure proper fire safety measures and address aesthetic considerations to maintain visual harmony. You must consider local building codes, which specify safe distances from heat sources and ventilation needs. Ensuring your installation meets filtration efficiency standards helps protect indoor air quality and prevents dust buildup.

AC Infinity AIRPLATE S5, Quiet Cooling Fan System 8" with Speed Control, for Home Theater AV Cabinets

An ultra-quiet UL-certified fan system designed for cooling cabinets that requires minimal noise.

As an affiliate, we earn on qualifying purchases.

Electrical Safety and Compliance Considerations

Ensuring electrical safety starts with proper grounding and bonding standards to prevent shocks and equipment damage. You also need to follow overcurrent protection requirements to avoid overloads that could cause fires or failures. Additionally, using correct wiring and clear labeling helps maintain safe operation and easy troubleshooting. Regular inspections and adherence to safety codes ensure ongoing compliance and reduce risks.

Grounding and Bonding Standards

Grounding and bonding are essential safety practices that help protect people and equipment from electrical faults. Following proper grounding standards ensures that any stray electrical current is safely directed to the ground, reducing shock risks. Bonding procedures connect non-current-carrying metal parts, preventing dangerous voltage differences. Adhering to these standards is vital for code compliance and safety. To implement effective grounding and bonding, consider these points:

- Verify grounding standards meet local electrical codes and manufacturer specifications.

- Use appropriately rated conductors and connectors for bonding procedures.

- Regularly inspect grounding and bonding connections for corrosion or damage.

Proper grounding and bonding protect your equipment from electrical faults and ensure safe operation, especially in environments with high heat and ventilation needs.

Overcurrent Protection Requirements

Overcurrent protection is a critical safety requirement that safeguards electrical systems from damage caused by excessive current flow. You must ensure that your projectors’ circuits are equipped with suitable devices like circuit breakers or fuse protection. These devices automatically disconnect power when current exceeds safe levels, preventing overheating, electrical fires, or damage to sensitive components. Circuit breakers are preferred for their quick response and ease of reset, while fuses provide reliable, one-time protection. Proper overcurrent protection not only complies with electrical codes but also protects your equipment and personnel. Always select protection devices rated appropriately for your circuit’s load and follow manufacturer guidelines. Regular inspection and testing of these devices are essential to maintain safety and guarantee ongoing compliance. Additionally, understanding electrical safety standards is vital to ensure comprehensive protection and adherence to regulations.

Proper Wiring and Labeling

Proper wiring and labeling are essential for maintaining electrical safety and ensuring compliance with relevant codes. Good cable management prevents tangling and reduces fire hazards, while clear labeling helps you identify circuits quickly. Use consistent color coding to distinguish between live, neutral, and ground wires, making troubleshooting safer and faster. Proper wiring practices also minimize the risk of shorts or overloads that could damage projectors or cause electrical fires. When installing, ensure all connections are secure and insulated. Keep wiring neat, organized, and accessible for inspections or future maintenance. Clearly label each cable and breaker to meet safety standards and streamline troubleshooting. Incorporating compliance standards into your wiring practices ensures your setup adheres to legal requirements and safety guidelines. This attention to detail helps maintain a safe environment and guarantees your project remains compliant with electrical regulations.

Proper Placement and Clearance Guidelines

To guarantee ideal airflow and prevent overheating, you need to carefully consider the placement of your projector. Follow proper projector placement and adhere to clearance guidelines to ensure efficient cooling. Keep your projector at least a few inches away from walls and other objects to allow air to circulate freely. Avoid placing it in enclosed or tight spaces where heat can build up. Make sure vents are unobstructed and that there’s enough space around the device for heat dissipation. Proper clearance guidelines help maintain excellent operating temperatures, extending the lifespan of your projector and ensuring consistent performance. Always check the manufacturer’s recommendations for specific spacing requirements, and never compromise on clearance to avoid overheating issues. Additionally, understanding the Self Watering Plant Pots system can remind you to regularly check ventilation pathways and prevent dust buildup that could impede airflow.

Ventilation System Design and Integration Tips

Designing an effective ventilation system for your projector involves thoughtful planning to integrate airflow pathways seamlessly. Focus on optimizing airflow to prevent hotspots and ensure reliable cooling. Proper ductwork layout is essential; avoid sharp bends and ensure smooth airflow to reduce resistance. Consider positioning vents strategically for efficient heat removal. Use dedicated intake and exhaust pathways to enhance airflow optimization, minimizing recirculation of warm air. Seal any gaps to prevent leaks and maintain consistent airflow. Select appropriate fans that match your system’s size and airflow needs. Regularly evaluate the ductwork layout during installation, ensuring it’s clean and free of obstructions. Additionally, choosing preppy dog names that reflect sophistication can inspire a more refined approach to your ventilation design. These steps help maintain proper ventilation, extend projector lifespan, and guarantee compliance with safety standards.

Inspection and Maintenance for Ongoing Compliance

Regular inspection and maintenance are essential to guarantee your projector’s ventilation system continues to operate efficiently and stay in compliance with safety standards. You should routinely check filters for dust and debris, performing filter maintenance when needed to prevent airflow restrictions. Ensuring filters are clean helps maintain proper cooling and reduces overheating risks. Additionally, consistent temperature monitoring is vital; use sensors or built-in systems to track operating temperatures and catch potential issues early. If temperatures rise beyond safe limits, investigate cooling components and airflow paths promptly. Regularly inspecting and maintaining these elements not only prolongs your projector’s lifespan but also keeps it compliant with safety codes. Staying proactive with filter maintenance and temperature monitoring safeguards your equipment and ensures reliable performance. Incorporating HEPA filtration can further improve air quality and protect internal components from dust buildup.

Common Mistakes and How to Avoid Them

One common mistake is overlooking adequate ventilation space around your projector, which can lead to overheating. Ignoring local regulations can also cause compliance issues and safety hazards. To avoid these pitfalls, always make certain proper clearance and stay informed about relevant rules in your area. Additionally, paying attention to ventilation requirements can help ensure your projector remains safe and functional during operation.

Overlooking Ventilation Space

Neglecting sufficient ventilation space around projectors can lead to overheating and performance issues. Without proper airflow, heat builds up, risking damage or shutdowns. One common mistake is blocking ventilation gaps, which hampers airflow obstruction and causes unnecessary heat retention. To avoid this, make certain there’s enough space around your projector for proper heat dissipation.

Consider these tips:

- Maintain clear ventilation gaps on all sides of the projector.

- Avoid placing objects directly in front of air vents.

- Check that no furniture or equipment obstructs airflow paths.

Ignoring Local Regulations

Failing to comply with local regulations can lead to legal issues, fines, or project delays. Ignoring local ordinances and permit requirements puts your project at risk. Many jurisdictions have specific rules for projector installation, ventilation, and heat management that must be followed. Skipping these steps may seem like a shortcut, but it can cause costly setbacks later. Always research local codes before starting work. Obtain necessary permits and ensure your setup meets all safety and compliance standards. Not doing so can result in inspections, fines, or even having to dismantle your installation. Stay proactive by consulting with local authorities or a compliance expert. Doing your due diligence helps avoid legal complications and guarantees your project proceeds smoothly and safely.

Frequently Asked Questions

How Do Different Projector Models Impact Ventilation System Design?

Different projector models impact your ventilation system design by varying in projector airflow and heat output. Higher-lumen models generate more heat, requiring increased ventilation capacity to prevent overheating. You should assess each model’s airflow needs and heat dissipation to size your vents and fans properly. This guarantees efficient cooling, maintains performance, and complies with safety standards, ultimately protecting your equipment and creating a safe environment.

Are There Specific Environmental Conditions That Affect Heat Dissipation?

Remember, heat rises and must escape, but environmental conditions can complicate this. High ambient humidity hampers heat dissipation, making it harder for projectors to stay cool. Airflow restrictions—like limited space or obstructions—also trap heat, risking overheating. You need to monitor these conditions closely, ensuring proper ventilation and avoiding areas with excessive humidity or tight spaces. Doing so keeps your projector running smoothly and prevents damage.

What Are the Consequences of Non-Compliance With Local Building Codes?

When you don’t comply with local building codes, you risk facing legal penalties like fines or project shutdowns, which can delay your work. More importantly, safety hazards may arise, such as overheating equipment or fire risks, putting people at risk. Non-compliance can also lead to costly repairs and damage to your reputation. Stay compliant to guarantee safety, avoid penalties, and keep your project running smoothly.

How Often Should Ventilation Systems Be Inspected for Safety and Efficiency?

You should inspect your ventilation systems at least once a year, guaranteeing maintenance schedules and inspection procedures keep everything running smoothly. Regular checks help catch issues early, improve safety, and maintain efficiency. During inspections, look for dust buildup, leaks, and faulty components. Don’t delay—consistent inspections protect your equipment and ensure compliance, saving you from costly repairs or violations down the line. Stay proactive, stay safe, and keep your systems operating at peak performance.

Can Portable or Temporary Projector Setups Meet Same Standards as Permanent Installations?

Portable or temporary projector setups can meet the same standards as permanent installations if you guarantee proper heat management and ventilation. Use adequate airflow, avoid blocking vents, and select equipment designed for mobile use. Regularly monitor temperature and airflow during operation, and follow safety guidelines. By taking these precautions, your portable or temporary setups can be as safe and efficient as fixed installations, ensuring ideal performance and compliance.

Conclusion

So, after all this, you’d think ensuring your projector’s safe and compliant would be straightforward. But here’s the irony: neglecting proper heat and ventilation can turn a simple setup into a costly disaster. It’s tempting to cut corners, yet those tiny oversights can lead to overheating, violations, or worse. So, next time you ignore the guidelines, remember—what seems like a minor shortcut might just be your project’s undoing.