To achieve consistent color uniformity and tackle tint corners or hotspots, start by ensuring your surfaces are properly prepared with clean, smooth finishes. For LED panels, inspect for uneven lighting or defective modules and recalibrate or replace components as needed. When spray painting, keep your spray gun at a consistent distance, apply thin coats with overlapping strokes, and adjust spray settings for even coverage. Mastering these steps helps create a seamless, professional finish—continue exploring to learn more about perfecting the process.

Key Takeaways

- Inspect LED panels for uneven lighting or faulty components causing hotspots and replace or recalibrate as needed.

- Ensure proper surface preparation and consistent spray technique to prevent tint corners and uneven color during painting.

- Maintain uniform LED placement and diffuser application to achieve consistent brightness and eliminate hotspots.

- Use thin, overlapping coats of paint with controlled pressure and nozzle settings to avoid tint corners and patchiness.

- Regularly inspect and maintain finished surfaces to detect and correct any emerging color inconsistencies promptly.

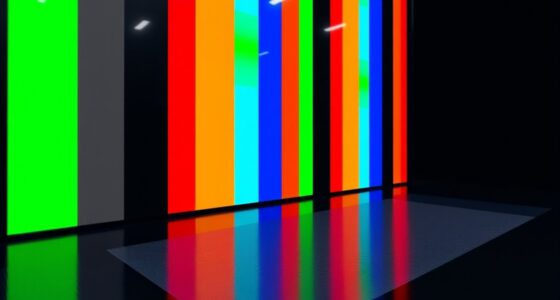

Have you ever noticed how some objects or surfaces display consistent color throughout, while others appear blotchy or uneven? This disparity often comes down to how the surface was finished or painted. Achieving uniform color, especially across large or complex surfaces, can be tricky, but understanding common issues like tint corners and hotspots can make a big difference. Whether you’re tackling LED panel repair or using spray painting techniques, addressing these problems guarantees a smooth, professional-looking finish.

Consistent surface color depends on proper finishing and avoiding tint corners and hotspots.

When working with LED panels, color uniformity is essential. If you notice tint corners or uneven glow, it could be due to inconsistent internal lighting or uneven application of the diffuser layers. Repairing or maintaining LED panels involves precise adjustments to ensure the light disperses evenly. Sometimes, uneven LED placement or faulty components create visible hotspots or darker areas. In such cases, careful inspection and targeted repairs restore the panel’s uniform brightness. For persistent issues, replacing certain modules or recalibrating the lighting system might be necessary. Proper LED panel repair requires patience and an understanding of the panel’s internal architecture, but it ultimately results in a seamless, evenly lit display. Additionally, understanding the contrast ratio of the display can help identify whether uneven brightness affects the perceived color uniformity.

Spray painting techniques also play a significant role in achieving color uniformity. When spray painting, uneven coverage often leads to hotspots—areas where the paint appears thicker—or tint corners where the color is noticeably different from the rest of the surface. To prevent this, you need to master your spray technique. Keep the spray gun at a consistent distance from the surface, and use smooth, overlapping strokes. Applying thin, even coats rather than one heavy layer helps the paint dry uniformly, avoiding drips or pooling that cause uneven coloration. Additionally, preparing the surface properly—cleaning, sanding, and priming—sets the stage for better results. Sometimes, adjusting the spray pressure or switching to a different nozzle size can improve flow and distribution, helping you avoid tint corners and hotspots.

Both LED panel repair and spray painting demand attention to detail. In LED panels, uniform lighting depends on proper internal calibration and component replacement. With spray painting, achieving a smooth, consistent finish hinges on technique, surface prep, and controlling application variables. Patience and precision are key. When you focus on these details, you’re more likely to eliminate tint corners and hotspots, resulting in a flawless, uniform appearance. No matter the project, understanding the root causes and applying the right fixes will boost your confidence and the quality of your work, ensuring that every surface or display looks its best without blotchy patches or uneven color patches.

Frequently Asked Questions

How Do Environmental Factors Influence Color Uniformity?

Environmental factors like lighting conditions and surface reflectance critically impact color uniformity. Poor or uneven lighting can cause color shifts and hotspots, while reflective surfaces may enhance or distort colors, creating tint corners. You should control lighting to guarantee even illumination and consider surface reflectance to minimize color variations. By managing these environmental factors, you can achieve consistent, uniform colors across your project.

Can Material Type Affect Tint Corners and Hotspots?

Yes, material type can affect tint corners and hotspots. Material influence plays a significant role because different substrates react uniquely to coatings, causing variations in color distribution. Coating variations, such as thickness or application method, can intensify or reduce issues like hotspots. To improve uniformity, select materials with consistent absorption properties and guarantee precise coating application. Regular testing and adjustments help you achieve better color consistency across all surfaces.

What Are the Best Tools for Detecting Color Inconsistencies?

Did you know that over 80% of quality issues stem from color inconsistencies? To detect them effectively, you should use a calibrated spectrophotometer for precise measurements and a high-accuracy colorimeter. Regular spectrophotometer calibration ensures reliable data, helping you identify tint corners and hotspots early. Combining these tools provides a thorough view of color uniformity, enabling you to maintain consistent, high-quality finishes across your projects.

How Often Should Calibration Be Performed for Optimal Results?

You should perform calibration regularly, ideally every 1 to 2 weeks, to maintain ideal timing for color uniformity. The frequency depends on your workflow, environment, and equipment stability. Keep an eye on tint corners and hotspots, and recalibrate whenever you notice inconsistencies. Consistent calibration ensures your display stays accurate, preventing color issues from impacting your work. Regular checks help you catch problems early and keep your visuals consistent.

Are There Industry Standards for Acceptable Color Variation?

Yes, industry benchmarks set clear standards for acceptable color variation, typically defining specific color tolerance levels. You should aim for minimal deviation within these benchmarks to ensure consistent quality. Regular calibration helps uphold these standards, but always check your equipment against accepted color tolerance values to meet industry requirements. Staying within these accepted ranges guarantees your output remains uniform and professional, satisfying clients and industry expectations alike.

Conclusion

Now that you’ve seen how tint corners and hotspots can disrupt color uniformity, it’s clear that mastering this challenge isn’t just about fixing spots—it’s about understanding what’s truly at stake. Every adjustment you make could reveal a hidden layer of complexity, pushing you to think deeper. Are you ready to go beyond surface solutions? The real journey begins when you realize that perfect color uniformity might be more elusive—and more rewarding—than you ever imagined.