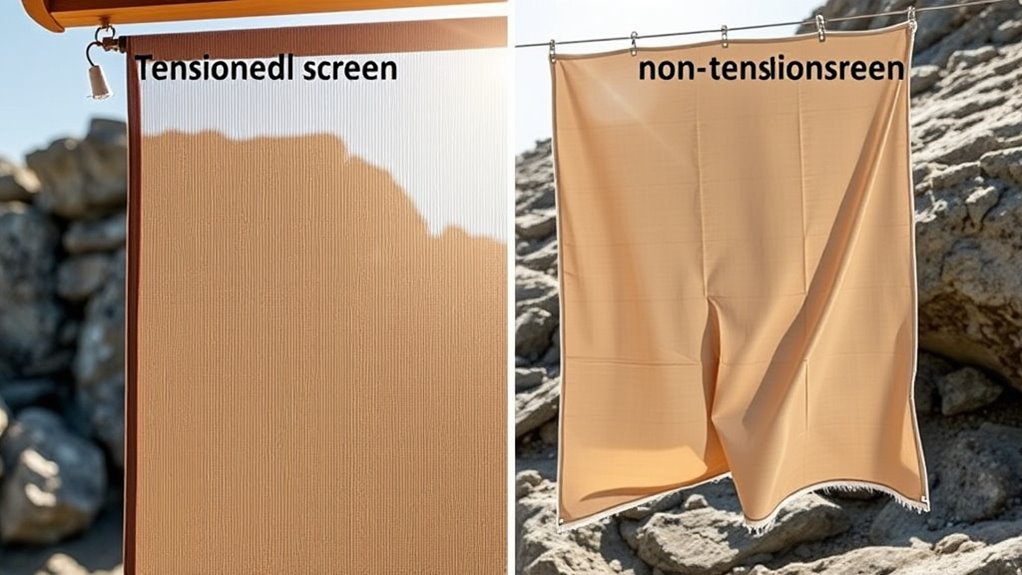

Tensioned screens are generally more durable because they keep fabric tight, reducing wear, wrinkling, and tearing, especially in harsh conditions. Non-tensioned screens are easier to install and repair but tend to have a shorter lifespan due to looser fitting and less resistance to environmental stress. Your choice depends on your needs for longevity, flexibility, and maintenance. To discover which option suits your application best, explore the key differences further.

Key Takeaways

- Tensioned screens maintain uniform tension, reducing wrinkles and increasing resistance to tearing, leading to higher durability.

- Non-tensioned screens are easier to install and repair but are more prone to slack, wrinkles, and quicker wear.

- Material quality and UV-resistant coatings significantly impact longevity; tensioned screens often use more durable, resilient fabrics.

- Tensioned designs better withstand environmental stresses like vibration, impact, and fatigue, enhancing long-term durability.

- Overall, tensioned screens typically offer superior durability and lower maintenance costs over their lifespan.

Understanding the Basic Design of Tensioned and Non-Tensioned Screens

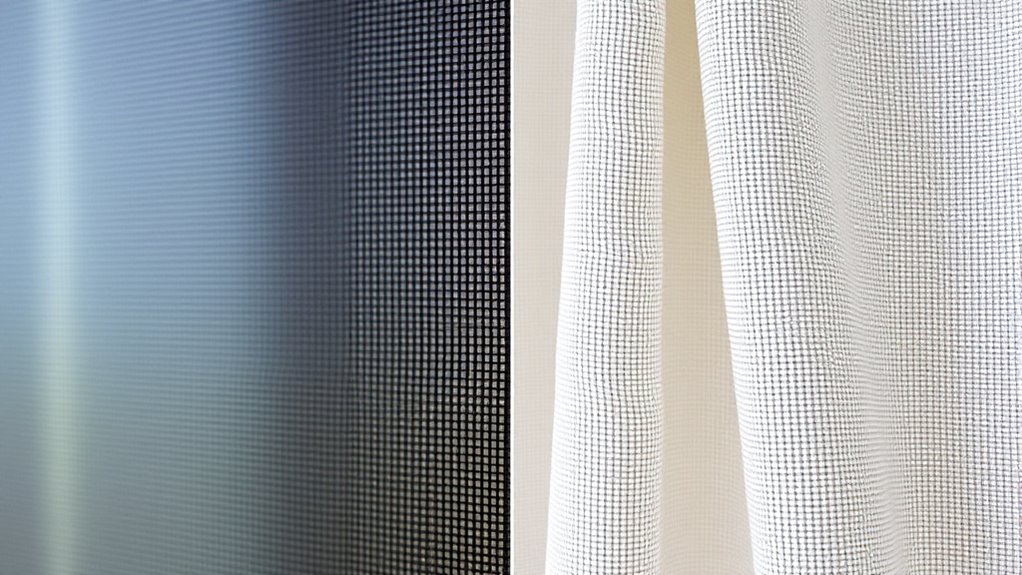

To understand the basic design of tensioned and non-tensioned screens, it’s important to recognize how their structures differ. With tensioned screens, the key is in the screen mounting system, which keeps the fabric taut and smooth. You’ll notice tension adjustment mechanisms—such as springs or tension bars—that allow you to tighten or loosen the fabric as needed. This setup ensures a consistent, wrinkle-free surface. Non-tensioned screens, on the other hand, rely on a different approach; the fabric is attached loosely to the frame, often with clips or staples, without tension adjustment features. This makes installation simpler, but it can result in less uniformity. Understanding these structural differences helps you choose the right screen based on your setup and visual quality needs. Additionally, proper installation techniques can significantly impact the durability and appearance of either screen type over time.

Material Composition and Its Impact on Screen Durability

The material composition of a screen directly influences its durability and performance over time. Choosing the right materials affects how well your screen withstands environmental stresses and daily wear. Here are key durability factors to contemplate:

- Fiber Type: Synthetic fibers like polyester resist UV damage better than natural fibers, extending lifespan.

- Coatings and Treatments: UV-resistant coatings protect against sun degradation, increasing durability.

- Mesh Density: Higher density materials offer more strength, reducing tearing and elongation.

- Core Material: Reinforced cores or composites add structural integrity, preventing sagging or breakage.

Installation and Maintenance Considerations for Different Screen Types

When installing screens, you’ll find tensioned ones often require precise tensioning procedures, while non-tensioned types may be simpler to set up. Maintenance access can vary, with tensioned screens sometimes making repairs more challenging due to their tight fit. Understanding these differences helps you plan for efficient replacement and repair strategies, ensuring smooth operation over time. Additionally, considering ease of maintenance during installation can save time and effort in the long run.

Tensioning Procedures and Ease

Tensioning procedures substantially impact both the installation and ongoing maintenance of screen systems. When performing screen tensioning, you need to follow specific steps to guarantee proper installation procedures. This affects how easily you can install and adjust the screens over time.

- Initial tension setup: You’ll tighten the screen evenly to avoid warping or slack.

- Tools required: Use specialized tensioning tools for precise control.

- Adjustment process: Tensioning must be done gradually to prevent damage.

- Periodic checks: Regularly inspect and re-tension the screen as needed.

Maintenance Access and Challenges

Proper maintenance access is essential to guarantee your screen system remains effective and durable over time. Non-tensioned screens typically offer easier access through simple removal of access panels, simplifying cleaning procedures. Tensioned screens, however, may require more effort to reach, often needing specialized tools or disassembly. To visualize, consider this table:

| Screen Type | Access Panel Presence | Maintenance Challenge |

|---|---|---|

| Non-tensioned | Usually straightforward | Easy to clean, quick inspections |

| Tensioned | Often less accessible | Requires more effort to detach |

| Both | Varies by design | Ensuring proper re-tensioning is key |

Additionally, understanding contrast ratio helps in assessing how well a screen can display dark scenes, which is crucial for home cinema setups. Efficient access guarantees you can perform regular inspections, cleanings, and minor adjustments without hassle, extending your screen’s lifespan.

Replacement and Repair Strategies

Replacing and repairing screen systems requires careful planning to guarantee minimal downtime and effective results. Your choice of screen material influences repair techniques and replacement methods.

- Assess the damage to determine if a simple repair or full replacement is needed, considering the screen material’s durability.

- For minor tears or damage, use patching or sealing techniques suited to the screen material to extend its lifespan.

- When replacing, remove the tensioned or non-tensioned screen carefully, ensuring you follow proper installation procedures for your specific type.

- Regular inspections help identify early signs of wear, enabling proactive repairs and reducing costly replacements.

Proper planning, understanding the screen material, and applying suitable repair techniques ensure your system remains functional and durable over time.

Resistance to Wear and Tear in Harsh Environments

When selecting screens for harsh environments, your focus should be on material strength and flexibility to withstand constant wear. You also need to take into account how well the material resists environmental factors like corrosion, temperature extremes, and abrasive particles. These capabilities determine whether tensioned or non-tensioned screens will hold up over time. Incorporating material durability considerations can significantly extend the lifespan of the screens in challenging conditions.

Material Strength and Flexibility

Material strength and flexibility are critical factors when choosing between tensioned and non-tensioned screens, especially in harsh environments where wear and tear are inevitable. You need materials that resist fatigue and maintain tensile strength over time. To guarantee durability, consider these points:

- High tensile strength helps prevent sudden failures under stress.

- Flexibility reduces the risk of cracking or breaking due to material fatigue.

- Durable materials withstand constant vibration and impact.

- Flexibility allows for better adaptation to structural movements, prolonging lifespan.

- Selecting materials with proven resistance to wear and tear ensures long-term performance under challenging conditions.

Choosing a material that balances strength and flexibility ensures your screens perform reliably under demanding conditions. This balance minimizes wear, extends service life, and reduces maintenance costs, making it essential for harsh environment applications.

Environmental Resistance Capabilities

In harsh environments, the ability of screens to resist wear and tear determines their longevity and performance. Tensioned and non-tensioned screens need strong environmental resistance, especially against corrosion and UV damage. Tensioned screens often offer better UV stability due to tighter tension, reducing sagging and exposure. Non-tensioned screens may be more vulnerable to corrosion if their materials aren’t corrosion-resistant. Consider the table below: compatibility factors

| Feature | Tensioned Screens | Non-Tensioned Screens |

|---|---|---|

| Corrosion Resistance | Usually better with coated materials | Dependent on material quality |

| UV Stability | Higher due to tension and design | Varies, often less stable |

| Wear & Tear | Generally more durable in tough conditions | Less resilient without proper treatment |

Flexibility and Adaptability to Various Screening Applications

Flexibility and adaptability are key factors that determine how well a screen performs across different applications. Your choice impacts overall efficiency and suitability for various tasks. When considering screen adaptability, focus on these aspects:

- Material properties: Different materials offer varied flexibility, allowing the screen to conform to unique shapes or conditions.

- Tensioning options: Tensioned screens provide a consistent surface, ideal for high-precision applications, while non-tensioned screens offer easier customization.

- Application versatility: Some screens excel in handling wet, dry, or abrasive materials, broadening their usability.

- Design features: Modular or adjustable designs enhance your ability to adapt to changing screening needs quickly.

- Performance consistency: Properly tensioned screens ensure uniform operation and reduce the likelihood of uneven wear or damage, which is crucial for maintaining durability over time.

Understanding these factors helps you select a screen that maximizes application versatility and meets your specific operational demands.

Cost Implications Over the Lifespan of the Screens

When evaluating the long-term costs of tensioned versus non-tensioned screens, it’s important to contemplate how each option impacts your budget over time. Tensioned screens generally offer better cost efficiency because they require less maintenance and have a longer lifespan, reducing replacement expenses. Non-tensioned screens might be cheaper upfront but can incur higher costs due to frequent repairs, re-tensioning, or premature replacement. Proper budget planning involves considering these factors to avoid unexpected expenses and guarantee optimal performance. While tensioned screens might seem more expensive initially, their durability often results in lower total costs over their lifespan. Additionally, choosing the right type can influence your overall arcade gaming experience, especially when considering the longevity of your equipment. Ultimately, understanding the cost implications helps you make smarter investment decisions and maintain a balanced budget in the long run.

Selecting the Right Screen Type for Long-Term Performance

Choosing the right screen type is essential for ensuring long-term performance and cost efficiency. To make the best choice, consider these factors:

Selecting the appropriate screen type ensures lasting performance and cost savings over time.

- Screen Noise: Tensioned screens often produce less noise during operation, which is crucial for noise-sensitive environments.

- Installation Complexity: Non-tensioned screens are generally easier and quicker to install, saving time and reducing labor costs.

- Durability: Tensioned screens tend to maintain tension longer, resisting sagging and wear over time.

- Maintenance Needs: Non-tensioned screens may require more frequent adjustments, impacting overall maintenance efforts.

Frequently Asked Questions

How Do Tensioned and Non-Tensioned Screens Affect Overall Operational Downtime?

Tensioned screens typically reduce operational downtime because they stay taut, minimizing issues like material fatigue and the need for frequent screen maintenance. Non-tensioned screens may require more adjustments and repairs over time, leading to increased downtime. By choosing tensioned screens, you guarantee smoother operation, less frequent maintenance, and better durability, ultimately keeping your production running efficiently with fewer interruptions.

What Environmental Factors Influence the Longevity of Tensioned Versus Non-Tensioned Screens?

Environmental factors like UV degradation and corrosion resistance markedly influence the longevity of your tensioned and non-tensioned screens. UV exposure causes material breakdown over time, especially if the screen isn’t UV-resistant. Corrosion from moisture or chemicals affects metal components, reducing lifespan. Tensioned screens often withstand these factors better due to their material properties and installation tightness, while non-tensioned screens may be more vulnerable without proper maintenance or protective coatings.

Are There Specific Industries That Benefit More From One Screen Type Over the Other?

You’ll find that certain industry-specific applications benefit more from tensioned screens, especially when material compatibility demands precise, stable screening, like in food processing or pharmaceuticals. Non-tensioned screens work better in industries where flexibility and ease of maintenance are priorities, such as mining or wastewater treatment. Your choice depends on the application’s environmental conditions, material type, and operational needs, ensuring the best durability and performance for your industry.

How Does Screen Tensioning Method Impact Repair and Replacement Procedures?

You’ll find that tensioned screens make repairs and replacements much easier—almost a breeze compared to non-tensioned options. Tensioning guarantees a tight, smooth surface, reducing installation challenges and preventing sagging that could cause damage. While the initial cost implications might be higher, the durability means fewer replacements long-term. With tensioned screens, you avoid the nightmare of loose or damaged fabric, saving you time, money, and headaches down the line.

Can Hybrid Screening Systems Combine Tensioned and Non-Tensioned Features Effectively?

Yes, hybrid screening systems can effectively combine tensioned and non-tensioned features through hybrid integration. By using advanced tensioning techniques, you can optimize screen durability and flexibility, allowing for easier maintenance and longer lifespan. This approach enables you to tailor the system to specific needs, balancing the benefits of tensioned screens’ durability with the simplicity of non-tensioned designs, ultimately improving overall performance and reducing downtime.

Conclusion

Choosing between tensioned and non-tensioned screens ultimately depends on your specific needs and environment. While tensioned screens may offer superior durability and easier maintenance, non-tensioned options can be more cost-effective upfront. Don’t let initial costs deter you; consider long-term performance and environmental demands. By understanding their differences, you’ll make an informed decision that guarantees your screening solution remains reliable and efficient for years to come.