To quickly improve color gamut and coverage compliance in 15 minutes, start by understanding the device’s color range and match it with standard color spaces using tools like spectrophotometers or gamut mapping software. Check coverage codes to confirm ink levels suit your substrate, adjusting as needed. Use standardized libraries like Pantone for fast referencing, and automate routine checks for consistency. Keep troubleshooting simple and consistent—if you keep going, you’ll discover even more ways to optimize your process.

Key Takeaways

- Understand the basics of color gamut and coverage codes to assess device capabilities and substrate interactions quickly.

- Use standardized color libraries like Pantone and RAL for rapid and accurate color referencing and consistency.

- Implement automated real-time checks within production workflows to ensure ongoing color compliance and reduce manual errors.

- Perform routine quick calibrations and sample tests during production to detect and resolve color or coverage issues early.

- Regularly review and adjust color management settings and substrate preparation to maintain quality and ensure standards compliance efficiently.

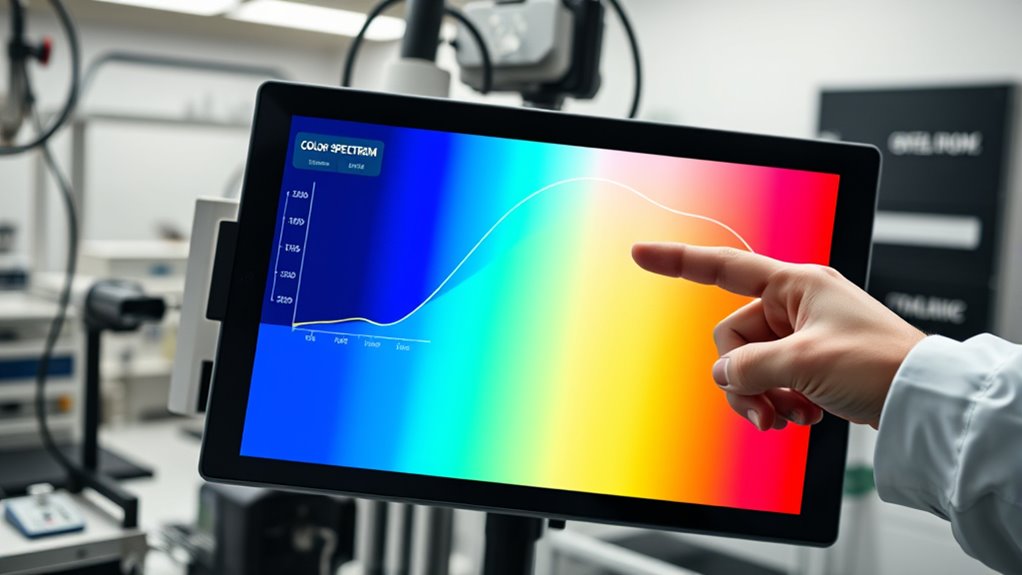

Understanding Color Gamut Basics

Understanding color gamut basics is essential because it defines the range of colors a device can reproduce. Spectral bandwidth plays a key role here—it determines how broad or narrow the spectrum of colors a device can display. A wider spectral bandwidth generally means better color accuracy, allowing for more vibrant and true-to-life images. When you know a device’s color gamut, you can assess how well it covers standard color spaces, ensuring your colors stay consistent across different screens and prints. This understanding helps you select devices that meet your needs, whether for professional work or casual viewing. Additionally, understanding how sound vibrations influence cellular regeneration through sound healing science can inspire innovative approaches to visual color optimization. Ultimately, grasping these fundamentals allows you to optimize color performance and achieve more precise, consistent results.

Recognizing Common Coverage Codes

Recognizing common coverage codes is essential because they quickly indicate how well a device can reproduce a specific color space. These codes help you assess color matching capabilities across different printers and substrates. Typically, coverage codes, such as 100%, 150%, or 200%, show the amount of ink or toner used to fill the color gamut. Understanding these codes allows you to evaluate whether your substrate preparation aligns with the intended color output. Proper substrate preparation ensures consistent coverage and minimizes color discrepancies. When reviewing coverage codes, consider how they relate to your printing process and substrate type. This knowledge helps you select the right equipment and optimize color accuracy, reducing waste and reprints. Additionally, recognizing personality traits in your workflow can improve team communication and efficiency. Recognizing these codes streamlines your workflow and improves overall color consistency.

Tools to Quickly Assess Color Gamut Compatibility

To quickly assess whether a device’s color gamut matches your printing needs, you can leverage specialized tools designed for this purpose. These tools perform spectral analysis and aid in color calibration, ensuring accurate color reproduction. For example, color management software compares device gamuts against standard color spaces, highlighting overlaps and gaps. You might use spectrophotometers to analyze color data directly from printed samples, verifying if the device’s color output aligns with your target range. Here’s a quick comparison:

| Tool Type | Function | Benefits |

|---|---|---|

| Spectrophotometers | Measure spectral reflections | Precise color calibration |

| Gamut Mapping Software | Visualize color gamut overlaps | Quick compatibility checks |

| Color Management Tools | Adjust device outputs | Consistent color accuracy |

| Spectral Analysis Devices | Analyze spectral data | Detect subtle color deviations |

A thorough understanding of color space concepts enhances the effectiveness of these tools and ensures accurate assessment of color gamut compatibility.

Interpreting Coverage Specifications for Different Substrates

Interpreting coverage specifications for different substrates is essential to guarantee your printing process meets quality and durability standards. The key factors to consider are substrate absorption and ink adhesion. Substrate absorption affects how much ink the material can take in; high absorption may require thinner layers to prevent bleeding or smudging, while low absorption needs more ink for vibrant coverage. Ink adhesion ensures the ink sticks properly without peeling or cracking over time. Check the coverage codes carefully—these specify the recommended ink levels for each substrate type. Understanding these specifications allows you to optimize ink application, avoid over- or under-coverage, and ensure consistent results. Adjust your process accordingly to achieve durable, high-quality prints tailored to each substrate’s unique properties. Additionally, being aware of regional divorce statistics can help you better understand market demands and client needs in different areas.

Using Standardized Color Libraries for Fast Reference

Using standardized color libraries streamlines your color referencing process, enabling you to quickly identify and match colors across different projects. They enhance color accuracy and reduce guesswork, making color calibration straightforward. With consistent references, you guarantee your colors stay uniform, no matter the substrate or device. To illustrate, consider this comparison:

| Color Library | Key Benefit |

|---|---|

| Pantone | Precise color matching |

| RAL | Standardized color coverage |

| NCS | Accurate color communication |

| Munsell | Consistent color calibration |

Using these libraries speeds up decision-making, minimizes errors, and ensures compliance with industry standards. With just a quick reference, you maintain reliable color accuracy and streamline workflows, saving time on color verification processes. Leveraging industry-standard color systems ensures your projects meet quality and consistency requirements efficiently.

Practical Steps to Verify Color Compliance

Verifying color compliance involves a series of clear, practical steps to guarantee your colors meet industry standards and project specifications. Start by ensuring proper color management practices across your workflow. Use calibrated monitors and devices to maintain consistency. Digital calibration is essential; regularly calibrate your displays and printing equipment to match color profiles precisely. Check your output against standardized color libraries or reference swatches to confirm accuracy. Use color measurement tools like spectrophotometers to objectively verify color matches. Document your calibration and verification processes for future reference. Implementing industry-standard color profiles can significantly enhance the accuracy of your color matching. By implementing these steps, you reduce errors and ensure your colors are compliant, saving time and avoiding costly reprints or adjustments later. Consistent color management and digital calibration are your best tools for rapid, reliable compliance verification.

Tips for Rapid Color Matching and Correction

To match and correct colors quickly, start by establishing a baseline with a calibrated monitor and standardized color profiles. This guarantees your color perception remains consistent throughout the process. Pay close attention to the pigment stability of your inks or materials, as unstable pigments can shift colors over time, complicating matching efforts. Use sample swatches or test prints to compare against your target colors, making small adjustments as needed. Rely on visual cues and digital tools to fine-tune hues and saturation rapidly. Consistently monitor color perception under controlled lighting conditions to avoid discrepancies. Additionally, understanding bank operating hours can help plan timely color correction sessions around branch availability or customer support hours. By focusing on stable pigments and accurate perception, you can streamline color correction and achieve precise results faster.

Automating Gamut and Coverage Checks in Workflow

Automating gamut and coverage checks streamlines your workflow by providing real-time feedback on color accuracy and material coverage. This integration enhances your color management process, ensuring consistent results across projects. With automated checks, you can catch issues early, reducing rework and delays. Workflow integration means these checks happen seamlessly within your existing production system, requiring minimal manual intervention. You’ll save time and improve precision, as software automatically verifies if your colors fall within specified gamuts and coverage parameters. By embedding these checks into your process, you create a more reliable, efficient production pipeline. This approach helps you maintain compliance with standards and minimizes costly errors, all while keeping your team focused on creative and strategic tasks. Incorporating safety and quality considerations into your process ensures that your toys meet high safety standards and durability requirements, reducing risks and enhancing overall product reliability.

Troubleshooting Common Gamut and Coverage Issues

When you encounter gamut or coverage issues, pinpointing the root cause quickly is essential to avoid delays. Start by reviewing your color management settings to ensure accurate color profiles. Check that your substrate preparation is ideal, as uneven or poorly prepared surfaces can cause coverage inconsistencies. Consider the following troubleshooting tips:

- Verify your color management workflow is correctly calibrated.

- Ensure substrates are clean, dry, and properly prepared before printing.

- Adjust ink density or color profiles if colors appear off.

- Use test prints to identify areas with poor coverage or color discrepancies.

- Remember that meditation and mental clarity can improve focus during troubleshooting, leading to more accurate adjustments.

Addressing these factors promptly helps resolve common gamut and coverage problems, saving time and maintaining print quality. Proper substrate preparation and accurate color management are key to achieving consistent results.

Implementing Quick Checks for Consistent Results

Implementing quick checks during the printing process helps you catch and correct issues before they escalate, guaranteeing consistent results. Regular quick checks improve color consistency by verifying that colors match your target standards. Use simple tools like color swatches or digital monitors to monitor output in real-time. This proactive approach enhances quality assurance by identifying deviations early, reducing waste and rework. Establish routine checkpoints at key stages, such as after calibration or color adjustments. Document your findings to track trends and make informed adjustments. Quick checks should be easy to perform and integrated seamlessly into your workflow, saving time without compromising quality. Additionally, understanding color gamut coverage ensures that your color range is accurately represented across devices, further maintaining consistency. By consistently applying these checks, you’ll maintain reliable color accuracy and ensure your prints meet the highest standards.

Frequently Asked Questions

How Often Should Color Gamut and Coverage Be Re-Evaluated During Print Jobs?

You should re-evaluate color gamut and coverage regularly throughout your print jobs, especially when there are changes in material properties or environmental conditions. Frequent checks ensure color consistency, preventing unexpected shifts. Reassess at key points, like material changes or midway through large jobs, to catch issues early. This proactive approach helps maintain accurate color reproduction, guaranteeing your prints stay true to your intended palette and meet quality standards.

Can Small Color Shifts Impact Overall Print Compliance and Quality?

Small color shifts are like tiny cracks in a glass; they can compromise overall print compliance and quality. Even minor variations in color measurement threaten color consistency, which is vital for professional results. These subtle differences may seem insignificant but can lead to mismatched branding or customer dissatisfaction. Regularly monitoring color measurement guarantees your prints stay true to your standards, preventing minor shifts from escalating into major quality issues.

What Are the Best Practices for Training Staff on Quick Color Checks?

You should incorporate color theory basics into your employee onboarding to guarantee staff understand color nuances. Conduct quick color checks regularly and encourage staff to trust their eyes for initial assessments. Use simple tools like color charts or spectrophotometers to verify accuracy. Provide hands-on training sessions, emphasizing practical application over theory, so your team quickly develops confidence in maintaining color consistency and compliance during printing processes.

Are There Industry Standards for Acceptable Color Coverage Deviations?

Yes, industry standards for acceptable color coverage deviations emphasize maintaining color accuracy and consistency. You should aim for deviations within specified tolerances—often around 2-3 Delta E units—to ensure quality. By focusing on precise color accuracy and consistent color coverage, you minimize discrepancies, uphold brand integrity, and meet industry expectations. Regular calibration and adherence to these standards help you attain reliable color reproduction, ensuring your work aligns perfectly with client and industry requirements.

How Do Environmental Factors Affect Color Gamut and Coverage Accuracy?

Environmental factors substantially impact color gamut and coverage accuracy. You should perform environmental calibration regularly to account for temperature, humidity, and ambient light changes, which can cause color shifts. These factors affect color stability, leading to deviations from expected coverage. By maintaining a controlled environment and calibrating your equipment frequently, you guarantee consistent color accuracy, reducing errors and ensuring your prints meet industry standards.

Conclusion

So, with these quick tips, you’ll master color gamut and coverage in just 15 minutes—who knew it could be so simple? Ironically, the more you rely on fast checks, the more you might overlook the nuances that truly guarantee color perfection. Remember, speed is great, but don’t let it fool you into skipping the details. Sometimes, taking a moment to double-check saves you hours of rework later. After all, quick wins shouldn’t cost you long-term quality.